Oil & Gas

Oil and gas are widely used in modern life. Oil fuels our cars, trucks and planes that underpin modern economies and lifestyles. Gas provides us with electricity and can be used for cooking and heating houses, buildings and water. By products from oil refining are used to produce plastics as well as pesticides, lubricants, waxes, tars and even asphalt for our roads.

Using activated carbon is a proven and effective way of removing contaminants and producing a pure product. Our carbon products can also be used to prevent damage to industrial equipment and recycle resources that can be reused later down the line.

Amine and Glycol Recovery

By treating a side stream of recirculating amine liquor to remove or reduce H2S/CO2 and other degradation compounds from natural gas, activated carbon can greatly prolong the service life of the amine. This capability protects other equipment in the circuit by managing the content of Heat Stable Salts (HSS) formed during stripping of the rich amine solution.

Similarly, the purification of glycol used in gas dehydration processes ensures optimum performance and reduces the risk of secondary contamination of the raffinate.

Activated carbon will:

- Minimise degradation of circulating solvent/absorbent inventory

- Remove harmful impurities from the end product

- Protect process equipment

- Maximise utilisation of absorbent/process chemicals

- Optimise operation of process equipment

HPNA Removal

During the hydrocracking process, certain compounds called Heavy Polynuclear Aromatics (HPNA) are formed in the hydrocracking reactors caused by condensation of aromatics and dehydrogenation of polynaphthenes. Once this happens, HPNAs are very hard to remove and build up to create critical fouling of heat exchangers and catalyst deactivation. These compounds are considered to be refractory in a hydrocracking process and are highly resistant to conversion in a hydrocracking reaction zone. It is critical to prevent this because it leads to reduced quality in production. Our activated carbon products are an ideal solution for removing these undesirable components.

Inquire Now

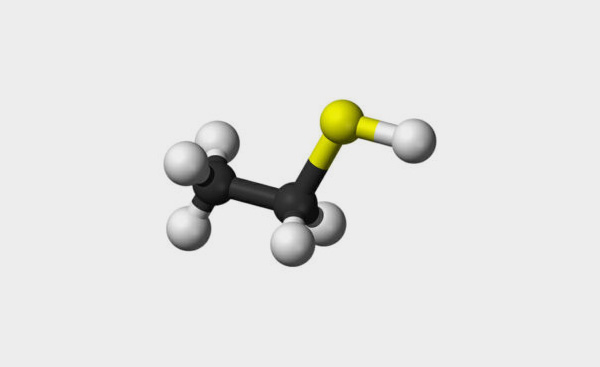

Mercaptan Removal and Fuel Sweetening

Mercaptans are organic compounds of hydrocarbons with sulphur and they have a characteristic bad smell, as well as corrosive properties in pipelines. Therefore, if mercaptans are present in high concentrations in natural gas, these must be removed to provide a suitable feedstock or end-product. To separate the mercaptans from natural gas in the sweetening plant, normally the process of oxidation of the mercaptans is performed. This is a catalytic process, often involving activated carbons.

Inquire Now

Activated Carbon for Amine Purification

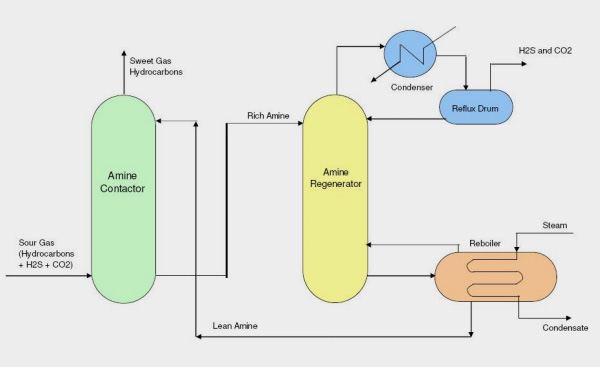

In the oil and gas industry, activated carbon is used in many applications. It’s commonly used in amine units for H2S and CO2 removal from hydrocarbon steams. Gases containing H2S or both H2S and CO2 are commonly referred to as sour gases.

Activated carbon removes contaminants from the amine solvent, reducing foaming problems. The most commonly used amines in industrial plants are the alcohol amines MEA, DEA, and MDEA.

There are many different amines used in gas treating

- Mon ethanolamine (MEA)

- Di-ethanolamine (DEA)

- Methyl-di-ethanolamine (MDEA)

- Di-Iso-propylamine (DIPA)

- Amino-ethoxy ethanol; diglycolamine (DGA)

Yaks amine liquid filtration activated carbon can purify the recirculating amine to remove degradation products and dissolved hydrocarbons.

Inquire Now